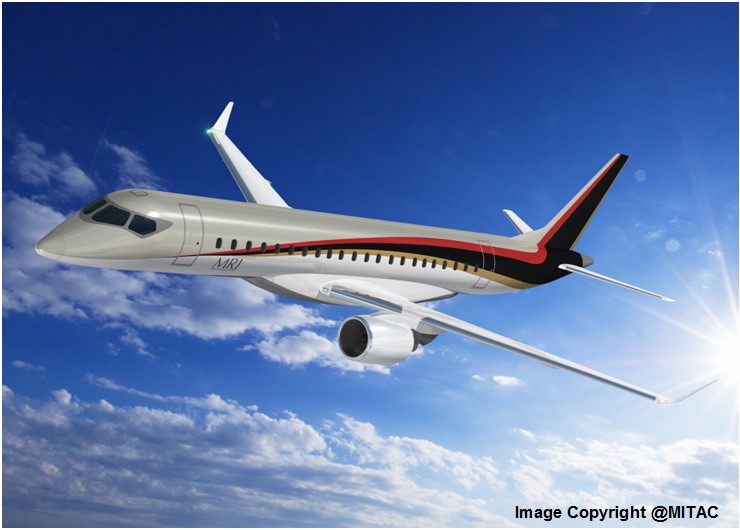

AEF began join venture work in 1973 together with Lycoming of the US; the initial stage, produced T53-L-13B turbine engines for UH-1H helicopters and T53-L-701A turboprop engines for Taiwan Chung-Hsing Trainer. In addition, the company also cooperated with Garrett (the predecessor of Honeywell) to produce the TFE731 turbofans for use with the advanced AT3 trainer. The two companies also established a joint venture, International Turbo Engine Corporation (ITEC), to collaborate on the development and production of the TFE1042 turbofan for use in the Taiwan’s IDF, as well as a derivative of the F124 turbofan. All of these experiences combined together have resulted in the AEF of today, the one true cornerstone of aero engine manufacturing in Taiwan.

With these experiences together have resulted in the AEF of today, which laying a solid foundation of aero engine manufacturing in Taiwan. AEF currently still provides ROCAF with logistic support, original components and spare parts for various planes; our major business however today is manufacturing for all of the major commercial aeroengine manufacturers in the world: General Electric Company (GE), Honeywell, Pratt & Whitney, and International Turbine Engine Company LLC (ITEC) all of the US, Rolls-Royce of England, Safran S.A. of France, Kawasaki Heavy Industries (KHI), IHI Corporation (IHI), and Mitsubishi Heavy Industries (MHI) all of Japan, Ltd...

Fully equipped with all manner of production capabilities, AEF currently manufactures over 600 differing items covering the entire spectrum of aeroengine technologies destined for customers both domestic and international.

Production of engine components applications.

AEF manufactures and supplies aero engine case components to the global aero engine community. We have three advanced case lines which produce over 10,000 engine cases every year. We are capable of producing all parts of aero engine cases, including air inlet, compressor section, combustor section, highpressure turbine section, lowpressure turbine section, etc..

Accountability, Innovation, Dedication and Customer orientation are the values used to shape our corporate culture. AEF/AIDC has launched lean manufacturing and ATeam 4.0 to further develop the process of the high value aerospace products, lead continuous growth of Taiwan’s aero engine industry, and build up a regional hub for aero engine manufacturing. Furthermore, by satisfying requirements of global customers with our mature manufacturing techniques and superior product quality, and by pursuing excellence to maintain competitive edge, AEF will establish itself a world-class professional technology centre dedicated to the manufacture of aero engines.

.jpg)