2016/4/14

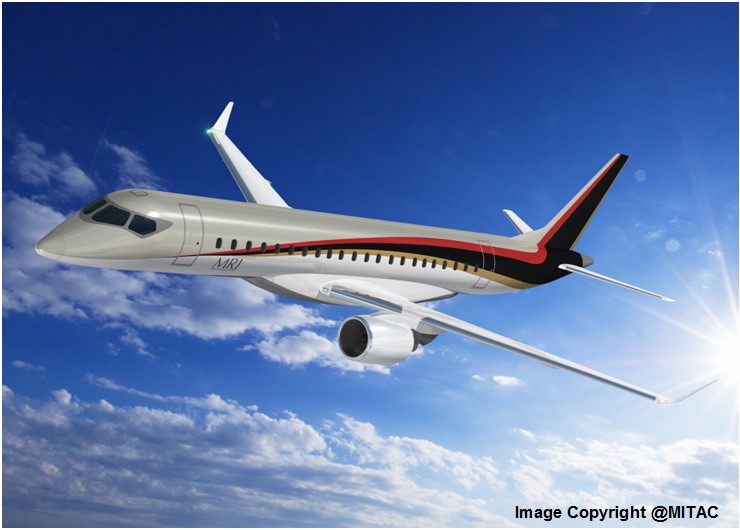

The AIDC’s Chairman, Liao Rong-Xin, inaugurated a new facility on April 14. The Engine Case Manufacturing Center (ECMC), at the factory located at Kang-Shan District in Kaohsiung. Approximately 200 plus representatives from industry, government, academia, research and overseas customers were invited to observe the unveiling ceremony with the traditional lion dance, and followed by a great program performed by a percussion band composed of autism members who filled with music passion and overcame challenges with the help from the consultant over the past 20 years. Their unyielding spirit in their life journey was respectable and their sophisticated performance was admirable. It was a lively and pleasant inauguration celebration.

Chairman Liao Rong-Xin said in his address, the ECMC was integrated with the industry 4.0 concept on its planning, design, machinery equipment, tool design, process verification, etc. Through the latest process monitoring system to collect necessary data by using a comprehensive analysis technique to establish the machinery equipment prevented quality and efficiency anomalies.

In addition, in response to the government’s advocacy of using domestic goods; 80% of all newly equipped machinery are domestic and have been verified by AIDC's customer Rolls Royce, including five-axis CNC machines which are planned to produce high value-added 2m-diameter engine case components mainly made of hot forged superalloy material and scheduled to start the production of Trent XWB high-pressure and medium-pressure turbine section in the second quarter of this year. The investment of machinery and equipment is in two phases; phase I is to meet Rolls Royce large engine case production needs, and phase II is to develop and produce a new generation of green energy engine cases such as GE Leap.

Chairman Liao said, AIDC and its downstream partners teamed up as A-team 4.0 and worked by a complementary function to meet customers’ demands. They will combine the new with its existing 1st & 2nd ECMC’s, Magnate Technology Co., Chenfull International Co., Chung Hsin, along with more than 20 outsourcing partners are to become a world-class engine case manufacturing center to reach a new milestone.

To meet the escalating demand of engine components from GE, RR, P&W, and others AIDC has established the 1st ECMC in 2000, mainly for GE and the 2nd ECMC in 2004, exclusively for RR, becoming a leading manufacturer of engine cases in Asia. In recent years, the awareness of environment protection and fuel consumption caused a wave of airplane replacement by airlines due to engine change. Owing to the increasing need, AIDC invested into the establishment of the 3rd ECMC which was inaugurated today with the assistance and the support of the Ministry of Economic Affairs.

The new ECMC costs NT$1.3 billion, including plant structure NT$0.2 billion and machinery NT$1.1 billion. The facility was designed and constructed as green building concept for carbon reduction, with 138 meters length, 56 meters width, 19 meters height, and total floor area of 9,530 square meters, using the industry 4.0 automation intelligent system. The facility will efficiently produce large engine cases and become the main supply source of new generation commercial aircraft engines.

Chairman Liao Rong-Xin said in his address, the ECMC was integrated with the industry 4.0 concept on its planning, design, machinery equipment, tool design, process verification, etc. Through the latest process monitoring system to collect necessary data by using a comprehensive analysis technique to establish the machinery equipment prevented quality and efficiency anomalies.

In addition, in response to the government’s advocacy of using domestic goods; 80% of all newly equipped machinery are domestic and have been verified by AIDC's customer Rolls Royce, including five-axis CNC machines which are planned to produce high value-added 2m-diameter engine case components mainly made of hot forged superalloy material and scheduled to start the production of Trent XWB high-pressure and medium-pressure turbine section in the second quarter of this year. The investment of machinery and equipment is in two phases; phase I is to meet Rolls Royce large engine case production needs, and phase II is to develop and produce a new generation of green energy engine cases such as GE Leap.

Chairman Liao said, AIDC and its downstream partners teamed up as A-team 4.0 and worked by a complementary function to meet customers’ demands. They will combine the new with its existing 1st & 2nd ECMC’s, Magnate Technology Co., Chenfull International Co., Chung Hsin, along with more than 20 outsourcing partners are to become a world-class engine case manufacturing center to reach a new milestone.

To meet the escalating demand of engine components from GE, RR, P&W, and others AIDC has established the 1st ECMC in 2000, mainly for GE and the 2nd ECMC in 2004, exclusively for RR, becoming a leading manufacturer of engine cases in Asia. In recent years, the awareness of environment protection and fuel consumption caused a wave of airplane replacement by airlines due to engine change. Owing to the increasing need, AIDC invested into the establishment of the 3rd ECMC which was inaugurated today with the assistance and the support of the Ministry of Economic Affairs.

The new ECMC costs NT$1.3 billion, including plant structure NT$0.2 billion and machinery NT$1.1 billion. The facility was designed and constructed as green building concept for carbon reduction, with 138 meters length, 56 meters width, 19 meters height, and total floor area of 9,530 square meters, using the industry 4.0 automation intelligent system. The facility will efficiently produce large engine cases and become the main supply source of new generation commercial aircraft engines.

.jpg)