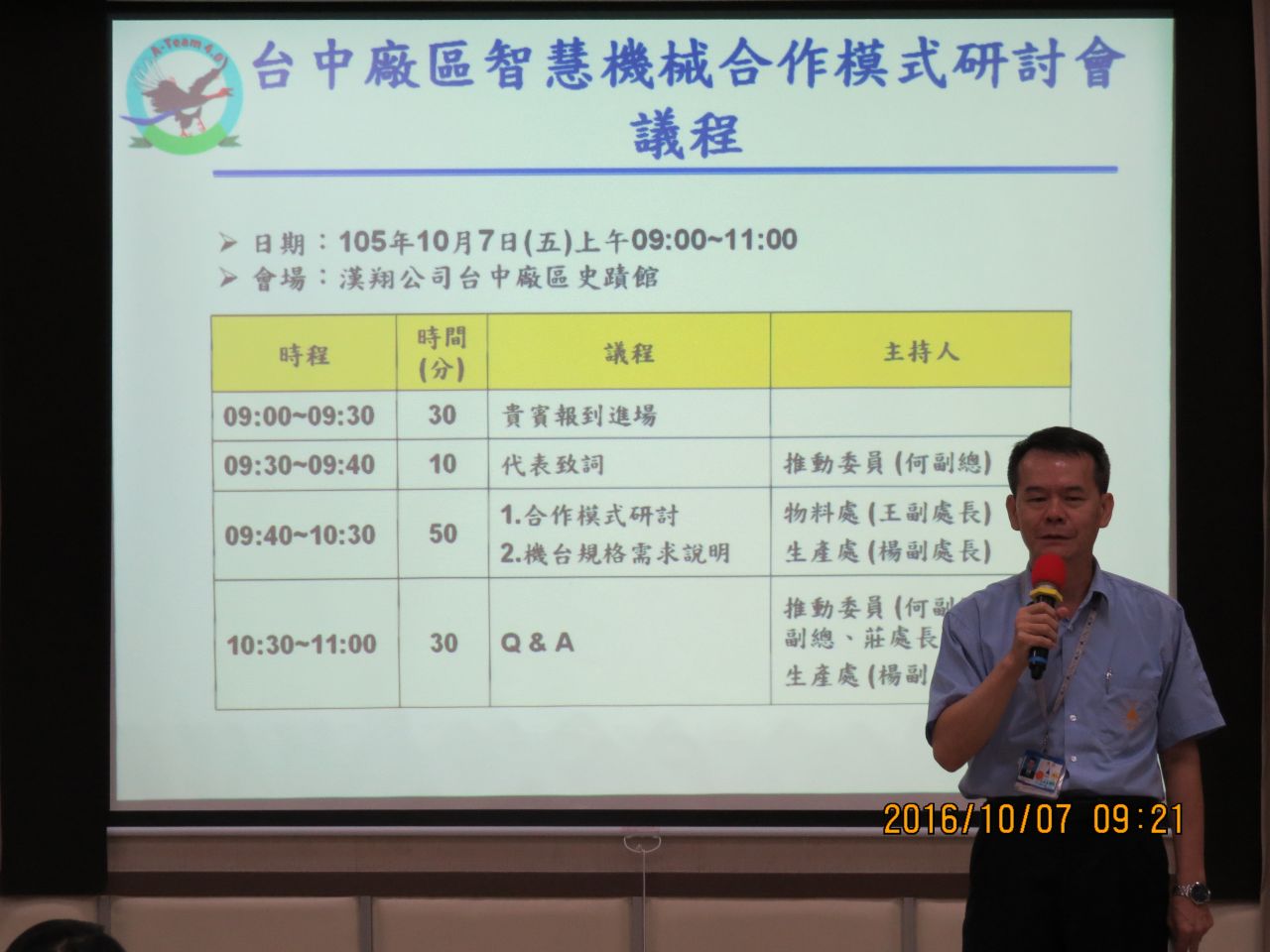

Aerospace Industry A-Team 4.0 Defines Intelligent Machinery Cooperation and Machine Performance Standards

2016/10/7

Taiwan Aerospace Industry A-Team 4.0 Alliance held a Seminar on Cooperation Approaches among Manufacturers of Intelligent Machinery and Equipment on October 7th, 2016 at AIDC’s Taichung Complex. During the seminar, cooperation timeframes and machinery performance standards were discussed and defined for various manufacturing processes.

The seminar on Intelligent Machinery Cooperation included subjects on Cooperative Approaches between AIDC and Manufacturers of Intelligent Machinery and Equipment; and on Specification Requirements of Aircraft Structure Machining Equipment. AIDC is to conduct capability and capacity evaluations of qualified manufacturers, leading to the possible opportunity of entering upon a Memorandum of Cooperation with AIDC to jointly develop high-performance aerospace intelligent machinery. Based on the manufacturing complexity of various parts, both parties will work out and define timeframes of cooperation and machinery performance standards, and further conduct a second phase screening mechanism with the intent to improve the level of cooperation. During the seminar, AIDC also introduced basic specifications and processing requirements of its machinery equipment for metal processing as well as five-axis composite material processing.

AIDC noted from the International Manufacturing Technology Show (IMTS) held in September 2016 in Chicago, there were six development trends in Intelligent Machinery Equipment consisting of; (1) a trend towards industry 4.0, (2) a trend towards automation, or unmanned operation, (3) an active development of intelligent machinery equipment in aero composite materials due to a mass amount of non-corrosive composite materials used in the aircraft industry, (4) a trend toward the use of a large number of digital molds, (5) a trend towards customization to meet customers’ demands; and (6) a trend toward providing comprehensive solution or total solution.

AIDC further pointed out that the trends seen from the IMTS event confirms the promotion of Taiwan’s Aerospace A-Team 4.0 and that such initiative is consistent with the world trend. The Seminar on the cooperative approaches and modes was conducted to upgrade the accuracy, reliability, completeness; and smart automation of the intellectual machinery equipment to the higher level as that of aerospace machinery equipment; for example by actively developing customization of specialized intelligent machinery equipment for manufacturing of advanced aerospace composite materials. AIDC expressed that it expected the cooperation all interested intelligent machinery manufacturers to implement Lean operations and to promote the Industry 4.0 towards achieving higher value and transformation in the domestic industry of intelligent machinery equipment.

The seminar on Intelligent Machinery Cooperation included subjects on Cooperative Approaches between AIDC and Manufacturers of Intelligent Machinery and Equipment; and on Specification Requirements of Aircraft Structure Machining Equipment. AIDC is to conduct capability and capacity evaluations of qualified manufacturers, leading to the possible opportunity of entering upon a Memorandum of Cooperation with AIDC to jointly develop high-performance aerospace intelligent machinery. Based on the manufacturing complexity of various parts, both parties will work out and define timeframes of cooperation and machinery performance standards, and further conduct a second phase screening mechanism with the intent to improve the level of cooperation. During the seminar, AIDC also introduced basic specifications and processing requirements of its machinery equipment for metal processing as well as five-axis composite material processing.

AIDC noted from the International Manufacturing Technology Show (IMTS) held in September 2016 in Chicago, there were six development trends in Intelligent Machinery Equipment consisting of; (1) a trend towards industry 4.0, (2) a trend towards automation, or unmanned operation, (3) an active development of intelligent machinery equipment in aero composite materials due to a mass amount of non-corrosive composite materials used in the aircraft industry, (4) a trend toward the use of a large number of digital molds, (5) a trend towards customization to meet customers’ demands; and (6) a trend toward providing comprehensive solution or total solution.

AIDC further pointed out that the trends seen from the IMTS event confirms the promotion of Taiwan’s Aerospace A-Team 4.0 and that such initiative is consistent with the world trend. The Seminar on the cooperative approaches and modes was conducted to upgrade the accuracy, reliability, completeness; and smart automation of the intellectual machinery equipment to the higher level as that of aerospace machinery equipment; for example by actively developing customization of specialized intelligent machinery equipment for manufacturing of advanced aerospace composite materials. AIDC expressed that it expected the cooperation all interested intelligent machinery manufacturers to implement Lean operations and to promote the Industry 4.0 towards achieving higher value and transformation in the domestic industry of intelligent machinery equipment.

.jpg)