2017/8/17

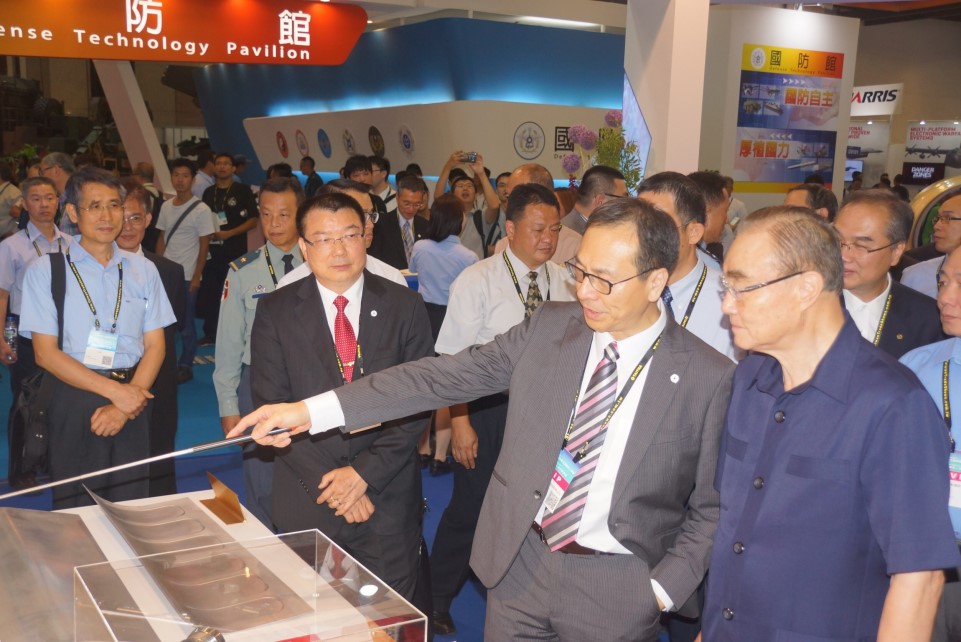

The biannual Taipei Aerospace & Defense Technology Exhibition opened today in Taipei. As forecasts from Airbus and Boeing indicates a market value of 5.3 to 6.1 trillion U.S. dollars over the next 20 years, AIDC as the leader of Taiwan’s aerospace industry has long started its layout for Taiwan’s aerospace industry. In the TADTE 2017, AIDC joined a dozen domestic suppliers in setting up displays at the aerospace exhibition hall with the focuses on; jet trainer local production, Taiwan Aerospace Industry A-Team 4.0 cross-sector alliance, industry supply chain integration efficiency, together with displays of critical engine parts, commercial aircraft capability and industrial technology services.

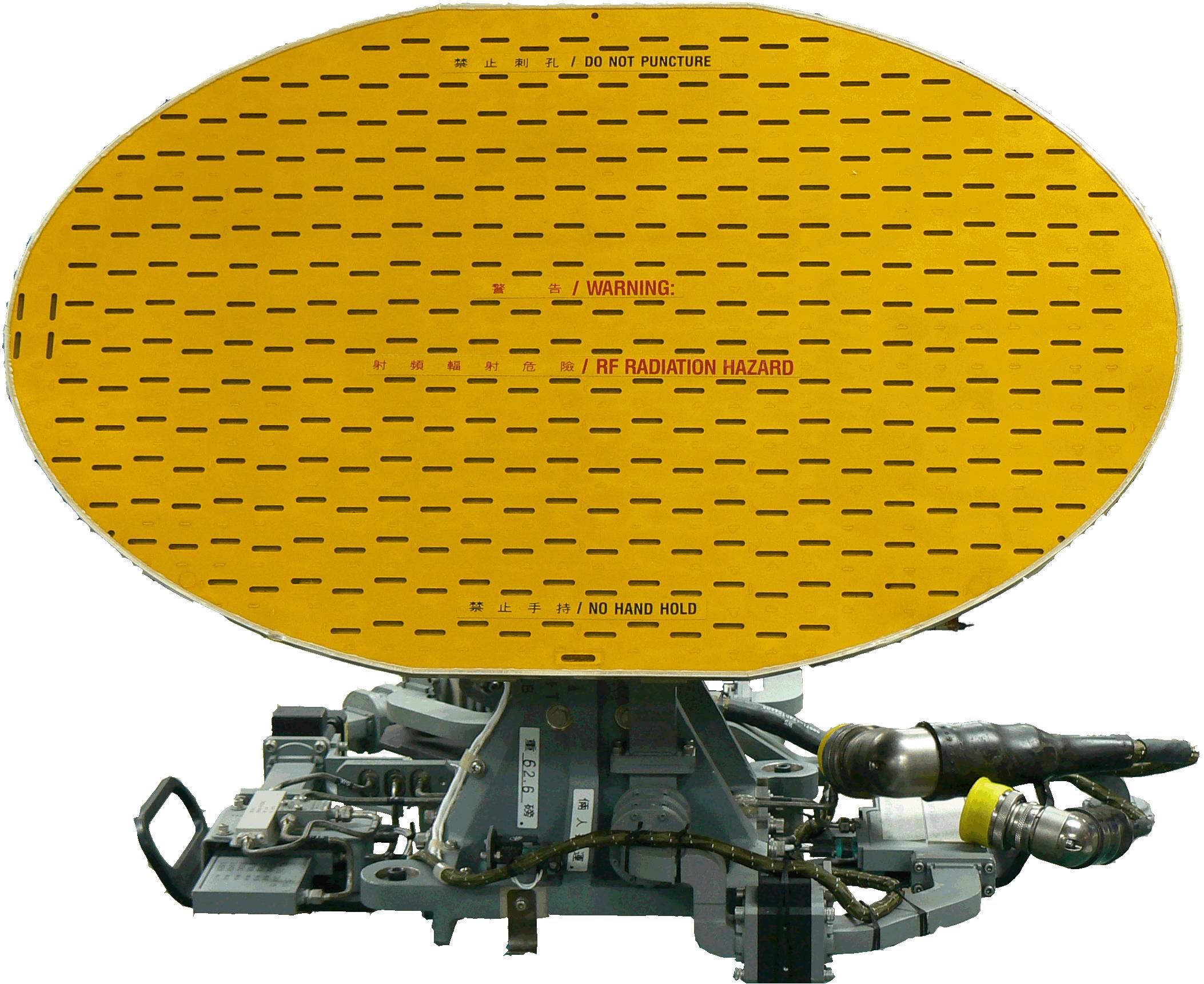

In compliance with government policy of “jet trainer local production” AIDC displayed for the first time the mockup and parts of the F124 engine, the powerplant of the Advanced Jet Trainer (AJT), trial production parts and avionics equipment. In addition, the commercial airplane seat which has passed the U.S. Federal Aviation Administration (FAA) dynamic test also made its debut.

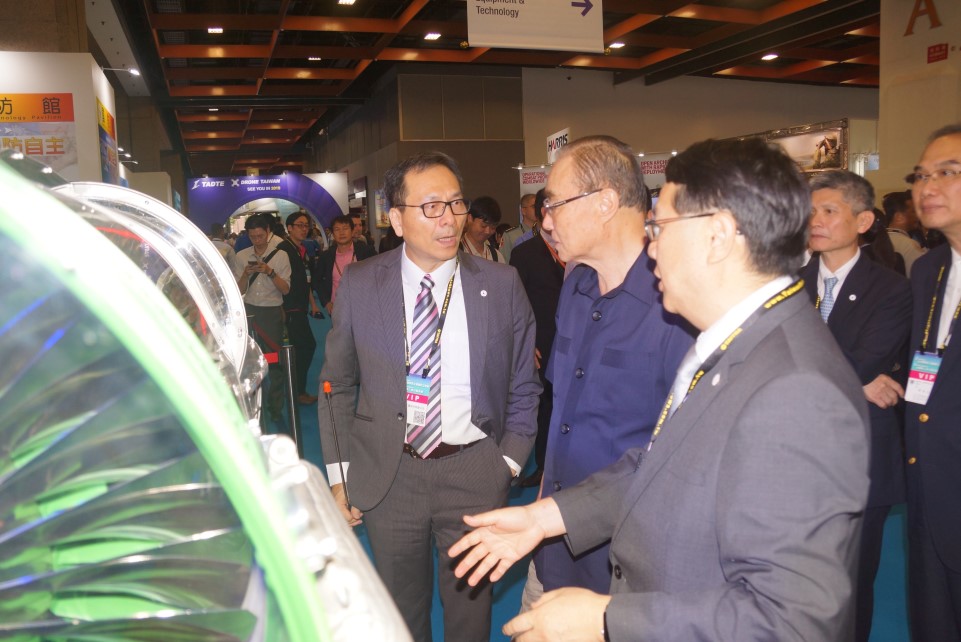

During the opening ceremony, under the witness of Vice President Chen Chien-jen, Chairman of Taiwan External Trade Development Council Mr. James C.F. Huang and Chairman of Taiwan Aerospace Industry A-Team 4.0 Alliance Mr. Anson Liao signed a MOA to join hands in providing domestic industries with assistance in exploring global market. Then in the afternoon, President of NCSIST Dr. Gao Chung-Hsing and AIDC Chairman Anson Liao signed an agreement for co-development, testing and introduction of additive manufacturing technology for the AJT program.

AIDC later held a press conference, announcing that it has been granted a Technical Standard Order Authorization (TSOA) for airplane seat by the Civil Aeronautics Administration (CAA) of Republic of China. Chairman Liao expressed gratitude for CAA’s guidance and support which made this TSOA possible. Last year, under the invitation of CAA, FAA representatives visited AIDC for evaluation and audit, and it is AIDC’s expectation to receive FAA design approval in the 4th quarter of this year to fulfill the intent of presenting its own brand product to the global commercial market.

Another focus of the press conference is the signing of purchase orders between AIDC and four major suppliers. Under the witness of Chairman Liao, AIDC President Nan-Juh Lin signed contracts with Magnate Technology and ChenFull International for the supply of LEAP engine case, with Tongtai Machine & Tool for the supply of equipment for the new Hanger Center of Excellence, and with Yefeng Aluminum for the supply of aluminum alloy plates. It is hoped that through the cooperation between leaders of individual field, we can be better positioned in the global aerospace community.

Chairman Liao emphasized that the announcements AIDC made today carries three important messages; First, “autonomous national defense, jet trainer local production; Second, the best opportunity for intelligent manufacturing; and Third, the integration of supply chains. He indicated that; Talent, Training and Resources are three vital elements of intelligent manufacturing. Resources refer to commercial business and the AJT program, and the forming of A-Team 4.0 provides business opportunities for the supply chain with training and the resources. For example, the new AEF ECMC #3 at AIDC’s Aero Engine Factory, 90% of its machinery is made in Taiwan, and that is a training ground in support of the government’s policy of “jet trainer local production”. AIDC shall continue to provide assistance with the local manufacturing of composite machinery, and shall provide them with verification field. It is believed that our aerospace intelligent composite manufacturing and Taiwan-made machinery will be well-received both in Taiwan and the world.

With regard to the first flight schedule of the AJT, Chairman Liao expressed his steadfast determination. He stated that it took the IDF eight years from development to first flight. When the AJT contract was signed in April with the target schedule of 3 years and 2 months for first flight (1048 days counting down from today), the time for development has been shortened by 60%. In comparison with the IDF program, the AJT is expected to adopt innovative and optimized technology to shorten the time for design, development, testing and verification, enhance total performance, maneuverability and reliability, and further enhance availability and reduce costs. To overcome global challenges, AIDC developed its own innovative management system, iAIDC Intelligent Manufacturing and Intelligent Management Platform, with which production efficiency and quality can be significantly improved, and further through the unity established by the A-Team 4.0 Alliance to reach the common goal of “Lean Production and Competitiveness Enhancement”.

Blank

In compliance with government policy of “jet trainer local production” AIDC displayed for the first time the mockup and parts of the F124 engine, the powerplant of the Advanced Jet Trainer (AJT), trial production parts and avionics equipment. In addition, the commercial airplane seat which has passed the U.S. Federal Aviation Administration (FAA) dynamic test also made its debut.

During the opening ceremony, under the witness of Vice President Chen Chien-jen, Chairman of Taiwan External Trade Development Council Mr. James C.F. Huang and Chairman of Taiwan Aerospace Industry A-Team 4.0 Alliance Mr. Anson Liao signed a MOA to join hands in providing domestic industries with assistance in exploring global market. Then in the afternoon, President of NCSIST Dr. Gao Chung-Hsing and AIDC Chairman Anson Liao signed an agreement for co-development, testing and introduction of additive manufacturing technology for the AJT program.

AIDC later held a press conference, announcing that it has been granted a Technical Standard Order Authorization (TSOA) for airplane seat by the Civil Aeronautics Administration (CAA) of Republic of China. Chairman Liao expressed gratitude for CAA’s guidance and support which made this TSOA possible. Last year, under the invitation of CAA, FAA representatives visited AIDC for evaluation and audit, and it is AIDC’s expectation to receive FAA design approval in the 4th quarter of this year to fulfill the intent of presenting its own brand product to the global commercial market.

Another focus of the press conference is the signing of purchase orders between AIDC and four major suppliers. Under the witness of Chairman Liao, AIDC President Nan-Juh Lin signed contracts with Magnate Technology and ChenFull International for the supply of LEAP engine case, with Tongtai Machine & Tool for the supply of equipment for the new Hanger Center of Excellence, and with Yefeng Aluminum for the supply of aluminum alloy plates. It is hoped that through the cooperation between leaders of individual field, we can be better positioned in the global aerospace community.

Chairman Liao emphasized that the announcements AIDC made today carries three important messages; First, “autonomous national defense, jet trainer local production; Second, the best opportunity for intelligent manufacturing; and Third, the integration of supply chains. He indicated that; Talent, Training and Resources are three vital elements of intelligent manufacturing. Resources refer to commercial business and the AJT program, and the forming of A-Team 4.0 provides business opportunities for the supply chain with training and the resources. For example, the new AEF ECMC #3 at AIDC’s Aero Engine Factory, 90% of its machinery is made in Taiwan, and that is a training ground in support of the government’s policy of “jet trainer local production”. AIDC shall continue to provide assistance with the local manufacturing of composite machinery, and shall provide them with verification field. It is believed that our aerospace intelligent composite manufacturing and Taiwan-made machinery will be well-received both in Taiwan and the world.

With regard to the first flight schedule of the AJT, Chairman Liao expressed his steadfast determination. He stated that it took the IDF eight years from development to first flight. When the AJT contract was signed in April with the target schedule of 3 years and 2 months for first flight (1048 days counting down from today), the time for development has been shortened by 60%. In comparison with the IDF program, the AJT is expected to adopt innovative and optimized technology to shorten the time for design, development, testing and verification, enhance total performance, maneuverability and reliability, and further enhance availability and reduce costs. To overcome global challenges, AIDC developed its own innovative management system, iAIDC Intelligent Manufacturing and Intelligent Management Platform, with which production efficiency and quality can be significantly improved, and further through the unity established by the A-Team 4.0 Alliance to reach the common goal of “Lean Production and Competitiveness Enhancement”.

Blank

.jpg)