2018/3/2

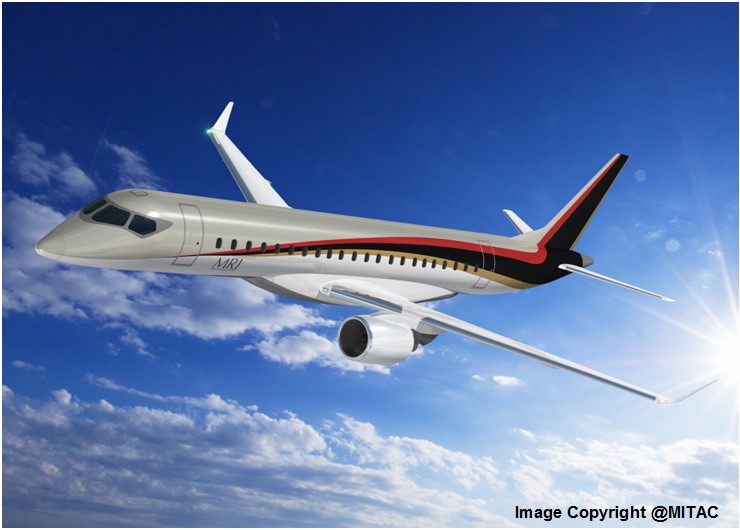

The Taiwan Aerospace Industry A-Team 4.0 held results presentation today (Mar. 1, 2018), with Aerospace Industry Development Corporation (AIDC), Evergreen Aviation Precision (EGAP), Marketech International Corporation and Yeong Chin Machinery Co., LTD (YCM) to respectively present lean achievements on different topics of process refinement, procedure improvement, production labor hour reduction and zero defect production lines and to share their own experience and acheivements. The President of the Alliance and also the Chairman of AIDC, Rong-Xin “Anson” Liao called on members of the Alliance to incorporate lean improvements in their internal culture and make it to be a habit instead of a slogan.

In the fierce competition environment, Taiwan’s aerospace industry is facing the challenge from the global supply chains on price-cutting requests from international giants such as Boeing, Airbus and Bombardier which continue to demand price reductions. How to reduce costs, shorten production time and improve quality is a subject that Taiwan’s aerospace industry needs to continue to face.

Chairman Liao stated that to ensure the success of lean improvement

,there are two beliefs which must be always adhered to. One is the recognition and support from high management and the other is to regard it as a long-standing and continuous management strategy as well as corporate culture;to continue improvements and not just the pursuit of perfection. Nearly 30% of participants were present from the vice presidential level and above at this presentation, which shows that companies increasingly pay more attention to promote leanness.

Chairman Liao further said that Toyota-style “lean production” is no longer sufficient, and it is necessary to introduce “smart manufacturing” in the future. As European and American aerospace industry manufacturers are actively developing smart manufacturing technologies, AIDC is also committed to promote “smart manufacturing” together with “lean production”. The company continues to seek alliances between aerospace industry and smart machinery, focusing on the intelligentization of machine equipment, intelligent manufacturing, and management. Airbus, Rolls-Royce, General Electric Aviation, Honeywell and other international aerospace giants all recognize AIDC for its achievements with intelligent manufacturing, elimination of production bottlenecks, prioritizing maneuvers, and successful reducing manpower requirements for repetitive tasks and reducing environmental pollution.

Since 2008, AIDC has successfully implemented lean initiative and related operations with setting up an exemplary production line as well as a lean promotion organization to develop lean operation in both production and office units to achieve employee training of all personnel. AIDC expects to continuously reduce operating costs and better assure the company’s competitiveness.

.jpg)