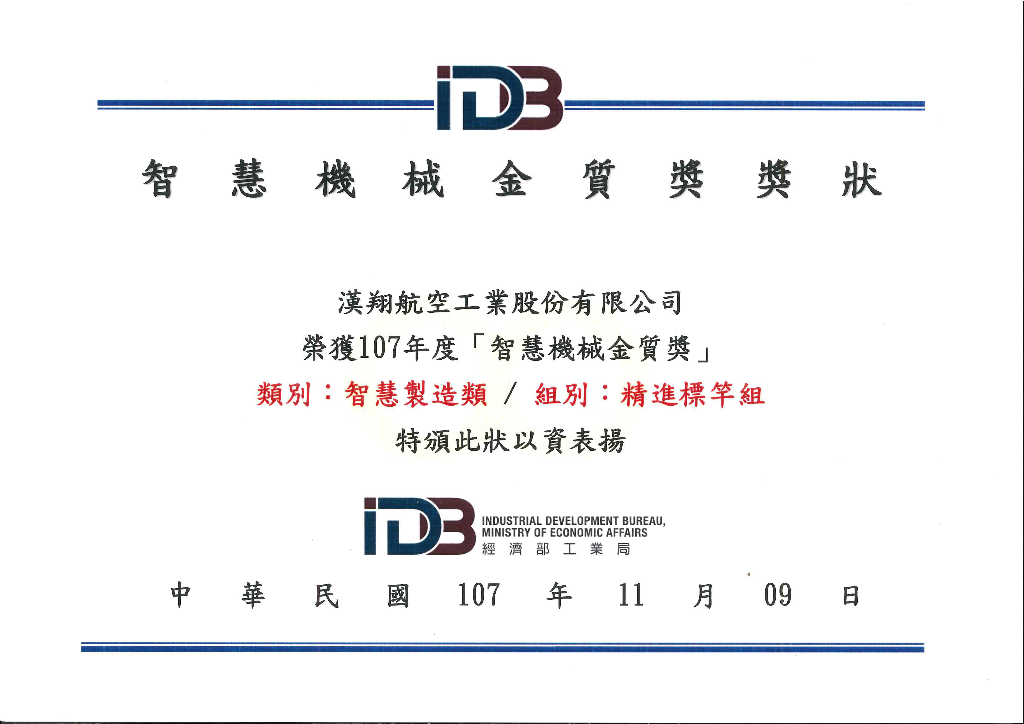

2018/11/9

AIDC was presented the “2018 Smart Machinery Model Enterprise Gold Award” by Deputy Minister of the Ministry of Economic Affairs (MOEA) Dr. Ming-Hsin Kung at an award presentation ceremony at the Taiwan-Germany Smart Machinery Forum organized by the Industrial Development Bureau of MOEA on November 9th.

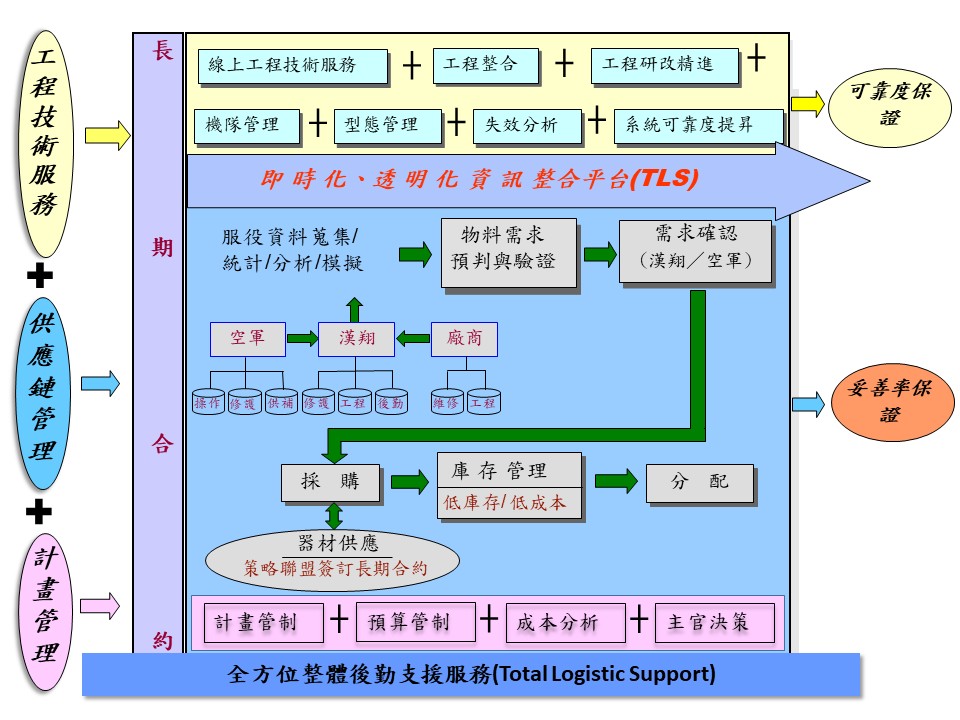

AIDC Chairman Anson Liao quoted Darwin’s Theory of Evolution on natural selection, survival of the fittest, and cited that to survive the ever-changing challenge AIDC adjusted itself by adopting both the Industry 4.0 and smart manufacturing. AIDC has continued to share and to lead the effort toward achieving a smart aerospace industry on Taiwan. AIDC’s smart manufacturing objective consists of three major parts: iAIDC, Policymaking War Room and iAI. Smart machinery, smart manufacturing and smart management were the strategies used for the promotion of smart manufacturing, and iAIDC, a smart manufacturing system platform, was developed to integrate systems including; iIoT, Big data, CPS and Production robotics.

“Smart machinery real-time monitoring and predictive maintenance” and “smart manufacturing and management of process”, together with lean production efforts, AIDC’s smart manufacturing has been upgraded from “post-implementation improvement” to incorporate a platform which provides; warning, prevention; and prediction. The iAIDC adopts collaborative robotics to perform highly polluting, hazardous, exhausting and repetitive work, implements smart product line, and promotes Big data analysis and AI improvements to achieve an overall upgrade and enhanced benefits.

To enhance competitiveness, AIDC President N.J. Lin stated that 2019 is AIDC’s “Year of Speedy Transformation”. The focus is to promote and implement SPEED (Smart, Process, Evolution, Effectiveness and Determination) in AIDC to achieve sustainable development by accelerating the transformation of smart manufacturing.

AIDC Chairman Anson Liao quoted Darwin’s Theory of Evolution on natural selection, survival of the fittest, and cited that to survive the ever-changing challenge AIDC adjusted itself by adopting both the Industry 4.0 and smart manufacturing. AIDC has continued to share and to lead the effort toward achieving a smart aerospace industry on Taiwan. AIDC’s smart manufacturing objective consists of three major parts: iAIDC, Policymaking War Room and iAI. Smart machinery, smart manufacturing and smart management were the strategies used for the promotion of smart manufacturing, and iAIDC, a smart manufacturing system platform, was developed to integrate systems including; iIoT, Big data, CPS and Production robotics.

“Smart machinery real-time monitoring and predictive maintenance” and “smart manufacturing and management of process”, together with lean production efforts, AIDC’s smart manufacturing has been upgraded from “post-implementation improvement” to incorporate a platform which provides; warning, prevention; and prediction. The iAIDC adopts collaborative robotics to perform highly polluting, hazardous, exhausting and repetitive work, implements smart product line, and promotes Big data analysis and AI improvements to achieve an overall upgrade and enhanced benefits.

To enhance competitiveness, AIDC President N.J. Lin stated that 2019 is AIDC’s “Year of Speedy Transformation”. The focus is to promote and implement SPEED (Smart, Process, Evolution, Effectiveness and Determination) in AIDC to achieve sustainable development by accelerating the transformation of smart manufacturing.

.jpg)