2010/10/13

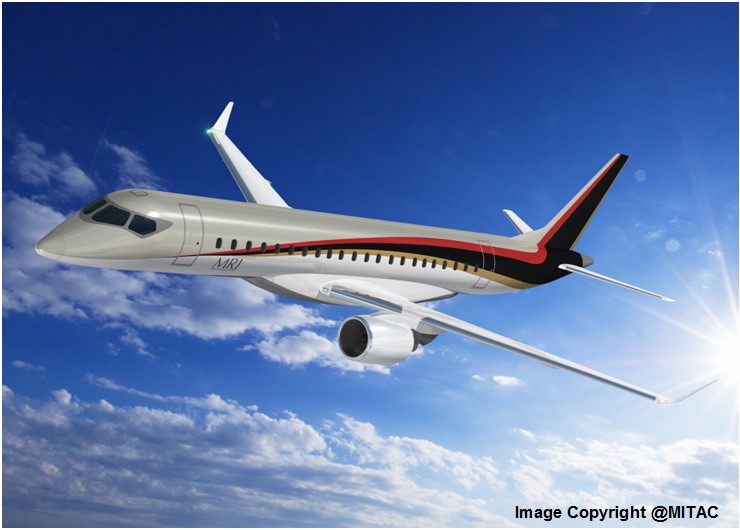

Aerospace Industrial Development Corporation (AIDC), has been performing a series of successful military as well as commercial aerospace programs in the past years, that include in military segment, development and maintenance of the Indigenous Defense Fighter (IDF) and the AT-3 Advanced Jet Trainer; in commercial segment, manufacture of aircraft and engine parts and components for Boeing, Airbus, Bombardier, General Electric, Rolls-Royce, Honeywell, etc. AIDC quality management system has been certified by several international leading aerospace companies and has been accredited by AS 9100 and ISO 9001, and issued Parts Manufacturer Approval (PMA) and Repair Station Certificate by Taiwan Civil Aeronautics Administration. In addition, AIDC has passed more than 500 special processes certification of customers and received accreditation for 8 Nadcap special processes.

From the establishment of its predecessor Aero Industry Development Center 40 years ago, AIDC has built up extensive capability in tooling design and parts manufacture. This year AIDC was selected for the “Innovative Product Award” for its development of the composite Aircraft Auxiliary Power Unit Inlet Duct at the 2010 Taiwan International Composites Industrial Technical Expo.

To satisfy light weight requirement, AIDC overcame various challenges in developing complicate composite inlet duct and structural parts and has had successful applications on the Bombardier CRJ-700 regional aircraft and LJ-45 business jet. It is estimated that the lightweight and heat-resistant composites will generate NT$100 millions revenue for the domestic aerospace industry.

.jpg)