2019/5/3

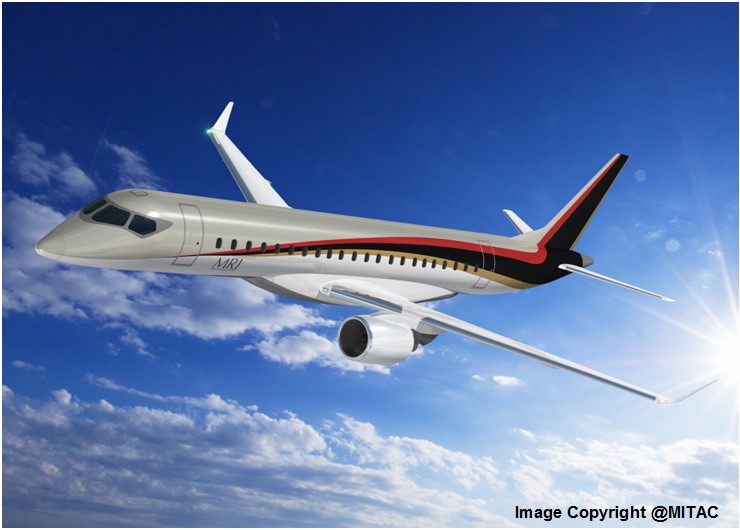

Amidst the booming international aerospace industry, AIDC conducted a ceremony celebrating the start of construction of its 4th and 5th case lines at its Gang-Shan complex today. The ceremony was attended by GE’s head of their procurement department in Asia, officials from the Industrial Development Bureau of the Ministry of Economic Affairs and the Economic Development Bureau of the Kaohsiung City Government and representatives from several domestic supply chain partners. It is believed this major investment will not only generate new momentum to the development of the domestic aerospace industry but will also create quality job opportunities.

In 2018, AIDC was awarded contracts to manufacture 17 LEAP Engine components by the aerospace engine leader GE and received the OEM business of high precision hot section components. In order to promote capabilities for its engine business, AIDC had begun construction of the 4th and 5th case lines to meet new business requirements and seize opportunities for future business growth. The investment totaled $2.229 billion N.T. dollars in which the facilities are expected to be completed in the first quarter of 2020 and to be inaugurated in the second quarter of 2020.

AIDC has experience and expertise in manufacturing the front compressor case, mid compressor case and combustion chamber diffuser case for LEAP engines. With the completion of the 4th and 5th case lines, AIDC will bring its business a step closer to the manufacture of turbine engine central structural components. Although hot section assemblies have traditionally been principally manufactured by aerospace manufacturers in Europe and the U.S., AIDC recently has gained a seven-year long-term order and has officially entered the supply chain of engine hot section, making it the first manufacturer in Asia to be certified to manufacture high precision hot section assemblies for GE.

It is expected that upon the completion of the 4th and 5th case lines, more than 200 job opportunities will be created which are principally dedicated for producing the central turbine structure for GE’s LEAP-1B engine. In tandem the new case lines will enhance the application of Industry 4.0 technologies and facilitate Lean production systems to advance development of Taiwan’s domestic aerospace engine industry.

.jpg)