Aviation Business Service

Technology Service

Information Service

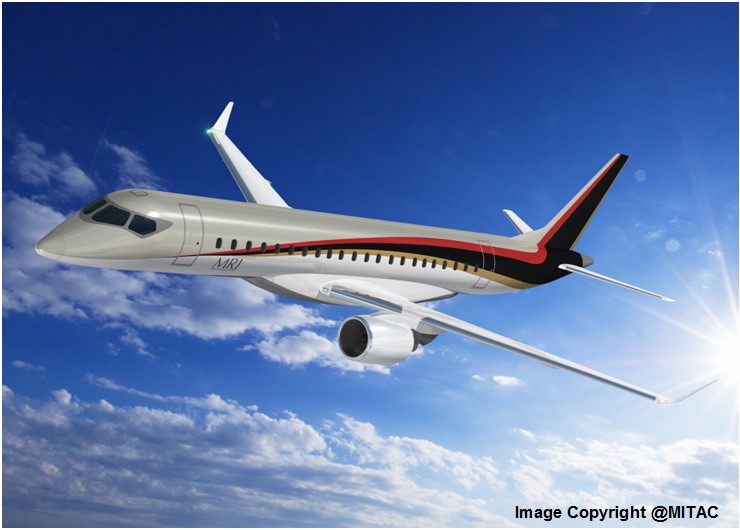

AIDC has the capabilities of design, manufacture, installation, and system integration for commercial jet aircraft auxiliary power Unit(CAPU). Parts has been certified by FAA and global key commercial aircraft companies. AIDC has been the global CAPU's parts supplier now.

Scope AIDC specializes in

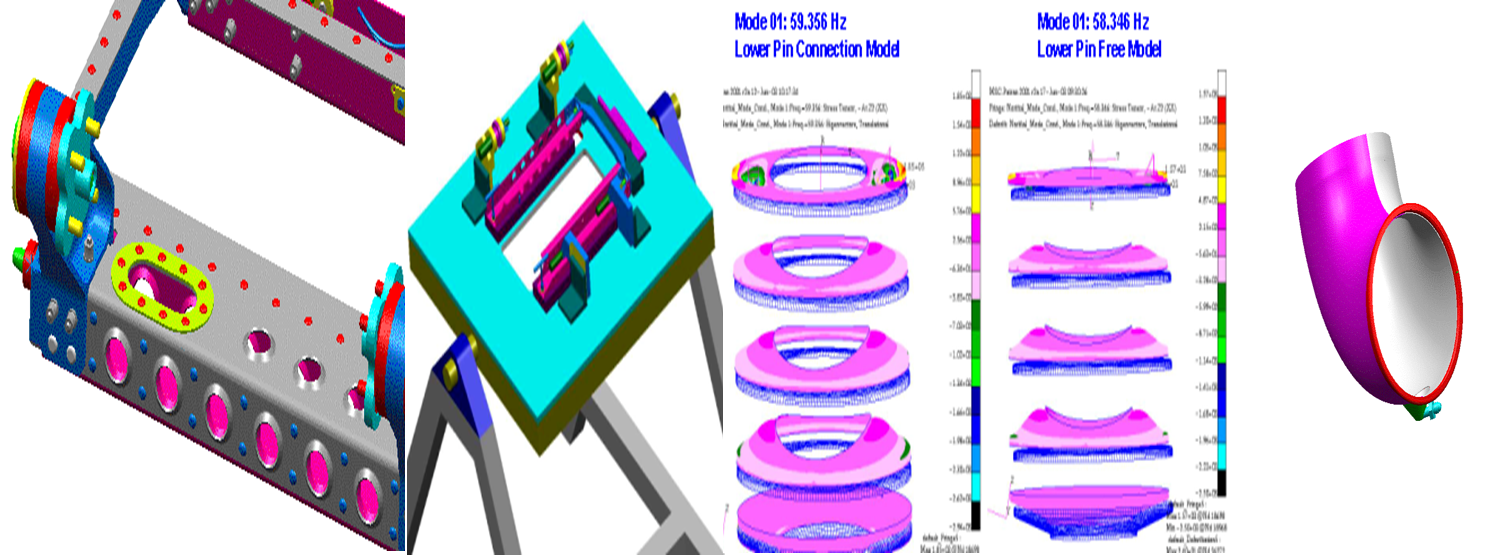

- Conceptual/Preliminary/Detailed design

- Stress/Load/Fatigue/Dynamic/Weight analysis

- Tooling Design/Fabrication

- Fabrication

- Testing

- After-market service for the whole life-span of aircraft.

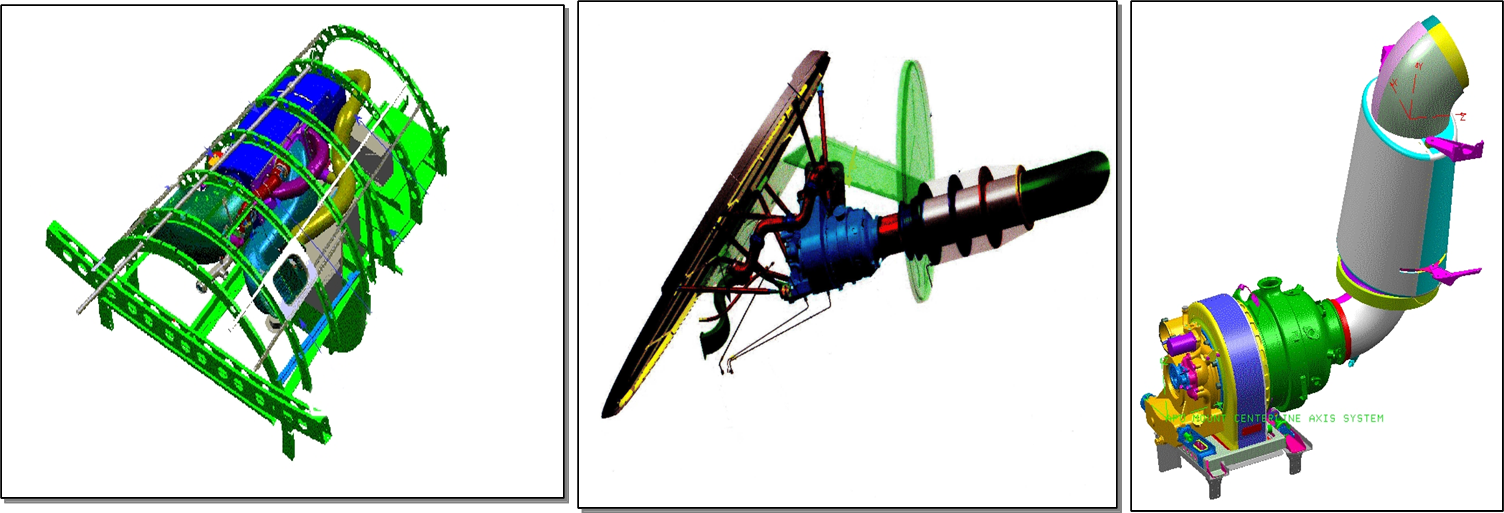

Scope* System Introduction

- either cradle mount or strut mount system including cradle, struts,brackets and isolators or strut with build-in elasto meric rod-end.

- inlet system with acoustic treatment including composite or metal duct, inlet seal.

- door actuating system including door, actuator, RVDT and driven mechanism.

- generator cooling system including duct and flexible hoses.

- bleed system including duct, ball joint and interfacing flanges.

- exhaust muffler including muffler body, acoustic liner, thermal blankets and supports.

- drain system including pipe for different systems and a drain mast.

Design Capability AIDC has the experience to perform the design of components of above systems

- conceptual design

- material selections

- detailed design

- detailed drawing creation

- static and dynamic analysis

- tooling design and manufacturing

- providing technical solutions to cost, weight and reliability

- generating substantiation test procedures and reports for QT, either for vibration/shock test or fluid susceptibility test, etc. to RTCA/DO-160E

- design FEMA

- reliability prediction analysis

- maintainability prediction analysis

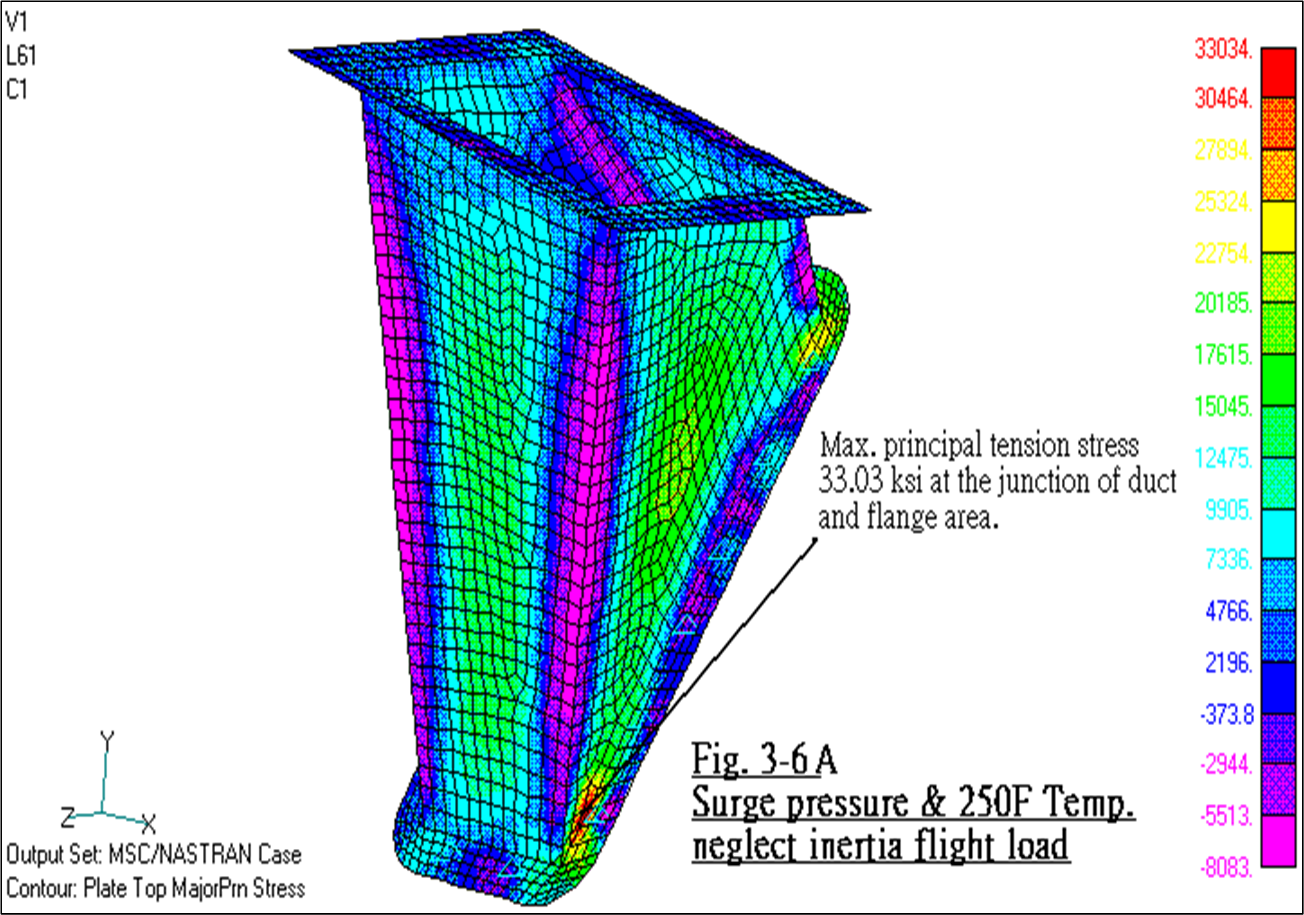

Analysis Capability Following items have been conducted

- static stress with margins of safety

- fatigue with life estimates

- load spectrum for fatigue

- damage tolerance with inspection interval

- strength substantiation

- sonic fatigue

- vibration and shock stress

- engine blade out

- rotor burst

- Heat transfer

- Acoustic analysis

Programs Experience: AIDC has the experience to perform the tooling design of components and parts fabrication , and we deliver the following programs with high performance of On Time Delivery rate and quality.

- RE100/Learjet 40/Learjet 45 APU Installation Kit – since 1997

- 36-150[HH]/Raytheon Hawker Horizon 4000 APU Installation Kit – since 1998

- RE220/Bombardier CRJ700/900 APU Installation Kit – since 2001

- RE220/Bombardier Global Express APU Installation Kit – since 2001

- 36-150[FN]/Daussault F7X APU Installation Kit – since 2003

.jpg)