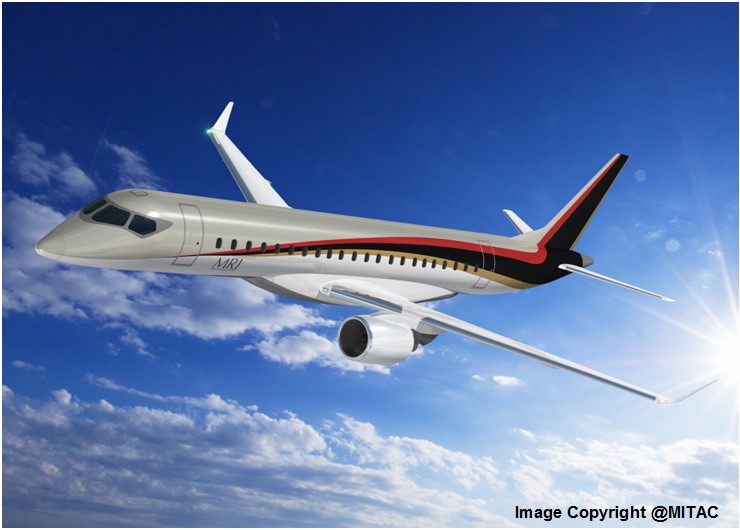

Traditional aircraft structure was assembled by hand using simple hand tool to affix detail parts such as bulkhead, support, stringer, and skin in pre-fit conditions, and drilling holes and riveting to achieve the basic aircraft structure.

Today the accumulation of experience and science and technology; modern aircraft structural assembly, incorporates the diversification of materials, improvement of the traditional fastener installation, and the use of automatic machines such as the Drivematic machine, Spacematic. These improvements have increased the quality and efficiency by a wide margin.

Aircraft has six major systems including fuel, ECS, hydraulic, flight controls, avionics and weapon systems. Functional testing is the important link between the aircraft reliability and its performance. During the last system installment work, all system parts must be correctly located, and equipped to allow for functional testing. This functional testing ensures all systems functions normally and in coordination with each other.

.jpg)